NEW

Mainstream Capacitor Shell Product Series Parameters

I. Introduction

A. Definition of Capacitors

Capacitors are passive electronic components that store and release electrical energy in a circuit. They consist of two conductive plates separated by an insulating material known as a dielectric. When voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. Capacitors are essential in various applications, from filtering signals in audio equipment to stabilizing voltage in power supplies.

B. Importance of Capacitor Shells in Electronic Devices

The shell of a capacitor plays a crucial role in its overall performance and reliability. It serves as a protective casing that shields the internal components from environmental factors such as moisture, dust, and mechanical stress. Additionally, the shell contributes to the thermal management of the capacitor, ensuring it operates within safe temperature limits. As electronic devices become more compact and complex, the design and material of capacitor shells have become increasingly important.

C. Overview of the Document's Purpose

This document aims to provide a comprehensive overview of the parameters associated with mainstream capacitor shell products. By understanding the various types of capacitor shells, their key parameters, performance metrics, applications, and emerging trends, manufacturers and engineers can make informed decisions when selecting capacitors for their specific needs.

II. Types of Capacitor Shells

A. Overview of Common Capacitor Types

Capacitors come in various types, each with unique characteristics and applications. The most common types include:

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications. They are made from ceramic materials and are available in various capacitance values.

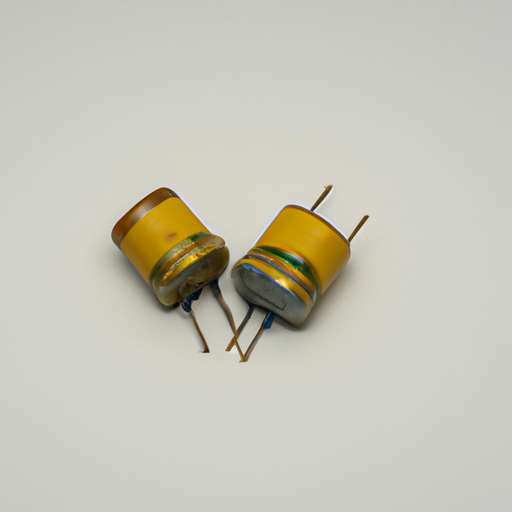

2. **Electrolytic Capacitors**: These capacitors are polarized and typically used in power supply applications due to their high capacitance values. They consist of an electrolyte and a metal oxide layer, which allows them to store more charge.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their reliability and low ESR. They are commonly used in audio and power applications.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance in a small package. They are often used in applications where space is limited, such as in mobile devices.

B. Material Composition of Capacitor Shells

The material used for capacitor shells can significantly impact their performance and durability. Common materials include:

1. **Metal Shells**: Often used for electrolytic and tantalum capacitors, metal shells provide excellent protection against environmental factors and enhance thermal conductivity.

2. **Plastic Shells**: Lightweight and cost-effective, plastic shells are commonly used for ceramic and film capacitors. They offer good insulation properties but may not provide the same level of protection as metal shells.

3. **Hybrid Shells**: Combining both metal and plastic materials, hybrid shells aim to leverage the benefits of both types. They can provide enhanced protection while maintaining a lightweight design.

III. Key Parameters of Capacitor Shells

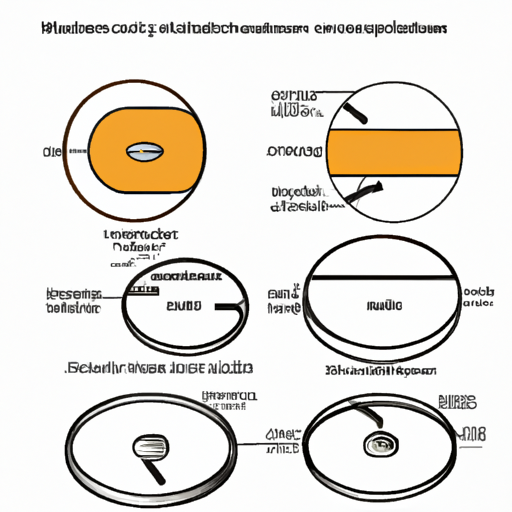

A. Physical Dimensions

1. **Diameter and Height**: The physical size of a capacitor shell is critical for fitting into electronic devices. Smaller dimensions are often preferred for compact designs, but they must also accommodate the required capacitance and voltage ratings.

2. **Lead Spacing**: The distance between the leads of a capacitor shell is essential for ensuring compatibility with circuit boards. Standard lead spacings help manufacturers design PCBs more efficiently.

3. **Mounting Options**: Capacitor shells can be designed for various mounting options, including through-hole and surface mount. The choice of mounting affects the overall design and assembly of electronic devices.

B. Electrical Characteristics

1. **Capacitance Value**: This parameter indicates the amount of charge a capacitor can store. It is measured in farads (F) and is a critical factor in determining the capacitor's suitability for specific applications.

2. **Voltage Rating**: The maximum voltage a capacitor can handle without breaking down is known as its voltage rating. Selecting a capacitor with an appropriate voltage rating is crucial for ensuring reliability and safety.

3. **Tolerance Levels**: Tolerance indicates the variation in capacitance from the specified value. Capacitors with tighter tolerances are often required in precision applications.

C. Thermal Properties

1. **Operating Temperature Range**: Capacitors must operate within specific temperature ranges to maintain performance. Exceeding these limits can lead to failure or reduced lifespan.

2. **Thermal Conductivity**: The ability of a capacitor shell to dissipate heat is vital for maintaining performance, especially in high-power applications. Materials with high thermal conductivity can help manage heat more effectively.

D. Environmental Resistance

1. **Moisture Resistance**: Capacitor shells must protect against moisture ingress, which can lead to corrosion and failure. This is particularly important in outdoor or humid environments.

2. **Chemical Resistance**: Capacitors may be exposed to various chemicals in industrial applications. The shell material must resist degradation from these substances.

3. **UV Resistance**: For applications exposed to sunlight, UV resistance is essential to prevent degradation of the shell material over time.

IV. Performance Metrics

A. Equivalent Series Resistance (ESR)

ESR is a critical parameter that affects the efficiency of capacitors. It represents the resistive losses within the capacitor and can impact the overall performance in high-frequency applications. Lower ESR values are generally preferred for better efficiency.

B. Equivalent Series Inductance (ESL)

ESL is another important performance metric that indicates the inductive characteristics of a capacitor. It can affect the capacitor's behavior in high-frequency circuits, making it essential to consider in design.

C. Self-Resonant Frequency

The self-resonant frequency is the frequency at which a capacitor behaves like a resistor rather than a capacitor. Understanding this frequency is crucial for ensuring that the capacitor performs effectively in its intended application.

D. Lifetime and Reliability Ratings

Capacitors are often rated for their expected lifespan under specific conditions. Reliability ratings help manufacturers and engineers select capacitors that will perform consistently over time, reducing the risk of failure in critical applications.

V. Applications of Capacitor Shells

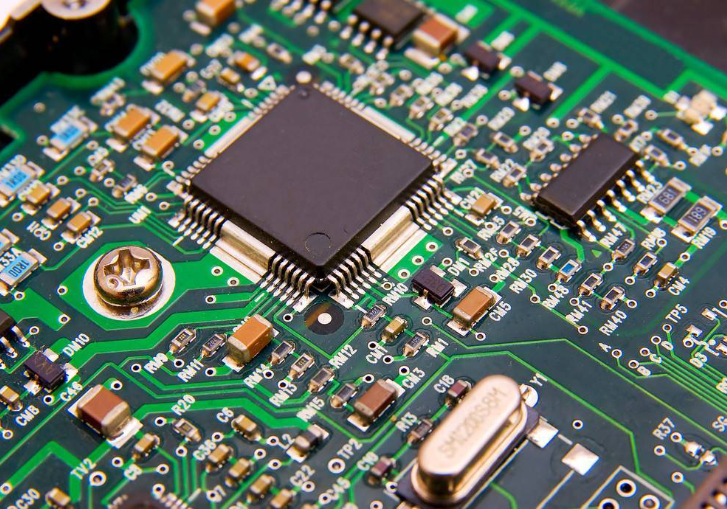

A. Consumer Electronics

Capacitor shells are widely used in consumer electronics, including smartphones, tablets, and televisions. Their compact design and reliability are essential for meeting the demands of modern devices.

B. Automotive Industry

In the automotive sector, capacitors are used in various applications, from power management systems to infotainment units. The durability and environmental resistance of capacitor shells are critical for ensuring performance in harsh conditions.

C. Industrial Equipment

Capacitors play a vital role in industrial equipment, where they are used for power factor correction, energy storage, and signal filtering. The robustness of capacitor shells is essential for maintaining performance in demanding environments.

D. Telecommunications

In telecommunications, capacitors are used in signal processing and power supply applications. The performance metrics of capacitor shells are crucial for ensuring reliable communication systems.

VI. Trends in Capacitor Shell Design

A. Miniaturization and Compact Designs

As electronic devices continue to shrink, the demand for smaller capacitors with efficient shells has increased. Manufacturers are focusing on miniaturization without compromising performance.

B. Eco-Friendly Materials and Manufacturing Processes

With growing environmental concerns, there is a trend towards using eco-friendly materials and sustainable manufacturing processes in capacitor shell production. This shift aims to reduce the environmental impact of electronic waste.

C. Innovations in Thermal Management

Advancements in thermal management technologies are leading to the development of capacitor shells that can better dissipate heat. This is particularly important for high-power applications where overheating can lead to failure.

VII. Conclusion

A. Summary of Key Points

In summary, the parameters associated with mainstream capacitor shell products are critical for ensuring their performance and reliability in various applications. Understanding the types of capacitor shells, their key parameters, and performance metrics is essential for selecting the right components for specific needs.

B. Future Outlook for Capacitor Shell Products

As technology continues to evolve, the demand for advanced capacitor shells will grow. Innovations in materials, design, and manufacturing processes will play a significant role in shaping the future of capacitor technology.

C. Importance of Selecting the Right Capacitor Shell for Applications

Selecting the appropriate capacitor shell is crucial for ensuring the reliability and efficiency of electronic devices. By considering the various parameters discussed in this document, manufacturers and engineers can make informed decisions that enhance the performance of their products.

VIII. References

A. Academic Journals

- IEEE Transactions on Electron Devices

- Journal of Applied Physics

B. Industry Reports

- Capacitor Market Analysis Report

- Trends in Electronic Components

C. Manufacturer Specifications

- Datasheets from leading capacitor manufacturers

- Technical guides on capacitor selection and application

This comprehensive overview of mainstream capacitor shell product series parameters provides valuable insights for engineers and manufacturers alike, ensuring that they are well-equipped to make informed decisions in their designs and applications.

Outline: The Role and Impact of Experts in Informational/Educational Content IntroductionThe Importance of Experts: In the age of information explosion, experts play a crucial role as disseminators of knowledge and guides in education. They not only provide authoritative information but also help the public understand complex concepts.Purpose of the Article: To explore how experts influence information dissemination and educational outcomes, analyze their roles in different fields, and the challenges they face. Part One: Definition and Role of Experts1. **Definition of Experts** - **Basic Characteristics**: Experts typically possess deep professional knowledge, extensive practical experience, and high academic achievements. - **Types of Experts in Different Fields**: Including scientists, educators, technical experts, social scholars, etc., experts in various fields have unique insights and influence within their respective domains.2. **Roles of Experts** - **Disseminators of Knowledge**: By giving lectures, publishing materials, and media appearances, experts help the public access the latest information. - **Drivers of Research and Innovation**: Engaging in research projects, experts drive the development of new technologies and theories. - **Analysts of Social Issues**: Conducting in-depth analysis of societal hot topics, experts provide solutions and policy recommendations. Part Two: The Role of Experts in Information Dissemination1. **Authority of Information** - **Enhancing Credibility of Information**: The involvement of experts can enhance the authority of information, as the public tends to trust expert opinions. - **Case Studies**: In public health crises (such as the COVID-19 pandemic), expert opinions and recommendations have significant influence on public behavior and policy-making.2. **Interpretation and Analysis of Information** - **Helping the Public Understand Complex Information**: Experts can translate technical terms into easily understandable language, helping the public digest complex information. - **Examples**: Experts in the field of climate change explain climate models and predictions in a simple and understandable way, enhancing public awareness of environmental protection.3. **Updating and Developing Information** - **Role in the Dissemination of New Knowledge and Technologies**: Experts' research and promotion in emerging technologies (such as artificial intelligence, gene editing) have advanced society's understanding and application of new technologies. - **Discussion**: How do experts stay updated in a rapidly changing information environment to ensure the accuracy and timeliness of information. Part Three: The Impact of Experts in Education1. **Design and Implementation of Educational Content** - **Role in Curriculum Development**: Experts participate in curriculum design to ensure the scientific and cutting-edge nature of educational content. - **Case Study**: Involvement of experts in education reform, promoting the implementation of STEM education, enhancing students' scientific literacy.2. **Teaching Methods and Strategies** - **Influencing the Choice of Teaching Methods**: Experts' research findings and teaching strategies help teachers improve their teaching methods. - **Discussion**: How collaboration between experts and teachers promotes educational innovation and enhances teaching effectiveness.3. **Students' Learning Experience** - **Impact of Expert Lectures and Workshops**: The involvement of experts can inspire students' interest in learning and broaden their horizons. - **Examples**: Projects involving experts (such as scientific experiments, social research) have enhanced the effectiveness of student capabilities, strengthening the integration of practice and theory. Part Four: Challenges and Opportunities for Experts1. **Information Overload and Misinformation** - **Challenges of the Information Age**: How experts maintain authority in the sea of information and avoid being overwhelmed by misinformation. - **Discussion**: How the public discerns the authority of experts and how experts enhance their credibility.2. **Impact of Technology** - **Influence of the Digital Age on the Role of Experts**: Online education and social media have changed the way experts interact with the public. - **Examples**: How experts' participation on online education platforms expands their influence through the internet.3. **Building Public Trust** - **Establishing Trust with the Public**: How experts build trust through transparent communication and active public engagement. - **Case Studies**: How successful and failed expert images influence public trust in experts. ConclusionSummarizing the Importance of Experts: Experts play an indispensable role in informational and educational content, influencing the dissemination of information and educational outcomes.Future Outlook: In emerging fields and technologies, the role of experts will continue to evolve, and adapting to change will be an important topic in the future. References- List relevant academic articles, books, and other resources to support the arguments and analysis in this article.---This outline provides a structure for an article on the role and impact of experts in informational and educational content, covering the definition, roles, influence, challenges, and future prospects of experts. Each section can be expanded into detailed content of 1000-2000 words as needed.Outline: The Role and Impact of Experts in Informational/Educational Content IntroductionThe Importance of Experts: In the age of information explosion, experts play a crucial role as disseminators of knowledge and guides in education. They not only provide authoritative information but also help the public understand complex concepts.Purpose of the Article: To explore how experts influence information dissemination and educational outcomes, analyze their roles in different fields, and the challenges they face. Part One: Definition and Role of Experts1. **Definition of Experts** - **Basic Characteristics**: Experts typically possess deep professional knowledge, extensive practical experience, and high academic achievements. - **Types of Experts in Different Fields**: Including scientists, educators, technical experts, social scholars, etc., experts in various fields have unique insights and influence within their respective domains.2. **Roles of Experts** - **Disseminators of Knowledge**: By giving lectures, publishing materials, and media appearances, experts help the public access the latest information. - **Drivers of Research and Innovation**: Engaging in research projects, experts drive the development of new technologies and theories. - **Analysts of Social Issues**: Conducting in-depth analysis of societal hot topics, experts provide solutions and policy recommendations. Part Two: The Role of Experts in Information Dissemination1. **Authority of Information** - **Enhancing Credibility of Information**: The involvement of experts can enhance the authority of information, as the public tends to trust expert opinions. - **Case Studies**: In public health crises (such as the COVID-19 pandemic), expert opinions and recommendations have significant influence on public behavior and policy-making.2. **Interpretation and Analysis of Information** - **Helping the Public Understand Complex Information**: Experts can translate technical terms into easily understandable language, helping the public digest complex information. - **Examples**: Experts in the field of climate change explain climate models and predictions in a simple and understandable way, enhancing public awareness of environmental protection.3. **Updating and Developing Information** - **Role in the Dissemination of New Knowledge and Technologies**: Experts' research and promotion in emerging technologies (such as artificial intelligence, gene editing) have advanced society's understanding and application of new technologies. - **Discussion**: How do experts stay updated in a rapidly changing information environment to ensure the accuracy and timeliness of information. Part Three: The Impact of Experts in Education1. **Design and Implementation of Educational Content** - **Role in Curriculum Development**: Experts participate in curriculum design to ensure the scientific and cutting-edge nature of educational content. - **Case Study**: Involvement of experts in education reform, promoting the implementation of STEM education, enhancing students' scientific literacy.2. **Teaching Methods and Strategies** - **Influencing the Choice of Teaching Methods**: Experts' research findings and teaching strategies help teachers improve their teaching methods. - **Discussion**: How collaboration between experts and teachers promotes educational innovation and enhances teaching effectiveness.3. **Students' Learning Experience** - **Impact of Expert Lectures and Workshops**: The involvement of experts can inspire students' interest in learning and broaden their horizons. - **Examples**: Projects involving experts (such as scientific experiments, social research) have enhanced the effectiveness of student capabilities, strengthening the integration of practice and theory. Part Four: Challenges and Opportunities for Experts1. **Information Overload and Misinformation** - **Challenges of the Information Age**: How experts maintain authority in the sea of information and avoid being overwhelmed by misinformation. - **Discussion**: How the public discerns the authority of experts and how experts enhance their credibility.2. **Impact of Technology** - **Influence of the Digital Age on the Role of Experts**: Online education and social media have changed the way experts interact with the public. - **Examples**: How experts' participation on online education platforms expands their influence through the internet.3. **Building Public Trust** - **Establishing Trust with the Public**: How experts build trust through transparent communication and active public engagement. - **Case Studies**: How successful and failed expert images influence public trust in experts. ConclusionSummarizing the Importance of Experts: Experts play an indispensable role in informational and educational content, influencing the dissemination of information and educational outcomes.Future Outlook: In emerging fields and technologies, the role of experts will continue to evolve, and adapting to change will be an important topic in the future. References- List relevant academic articles, books, and other resources to support the arguments and analysis in this article.---This outline provides a structure for an article on the role and impact of experts in informational and educational content, covering the definition, roles, influence, challenges, and future prospects of experts. Each section can be expanded into detailed content of 1000-2000 words as needed.Outline: The Role and Impact of Experts in Informational/Educational Content IntroductionThe Importance of Experts: In the age of information explosion, experts play a crucial role as disseminators of knowledge and guides in education. They not only provide authoritative information but also help the public understand complex concepts.Purpose of the Article: To explore how experts influence information dissemination and educational outcomes, analyze their roles in different fields, and the challenges they face. Part One: Definition and Role of Experts1. **Definition of Experts** - **Basic Characteristics**: Experts typically possess deep professional knowledge, extensive practical experience, and high academic achievements. - **Types of Experts in Different Fields**: Including scientists, educators, technical experts, social scholars, etc., experts in various fields have unique insights and influence within their respective domains.2. **Roles of Experts** - **Disseminators of Knowledge**: By giving lectures, publishing materials, and media appearances, experts help the public access the latest information. - **Drivers of Research and Innovation**: Engaging in research projects, experts drive the development of new technologies and theories. - **Analysts of Social Issues**: Conducting in-depth analysis of societal hot topics, experts provide solutions and policy recommendations. Part Two: The Role of Experts in Information Dissemination1. **Authority of Information** - **Enhancing Credibility of Information**: The involvement of experts can enhance the authority of information, as the public tends to trust expert opinions. - **Case Studies**: In public health crises (such as the COVID-19 pandemic), expert opinions and recommendations have significant influence on public behavior and policy-making.2. **Interpretation and Analysis of Information** - **Helping the Public Understand Complex Information**: Experts can translate technical terms into easily understandable language, helping the public digest complex information. - **Examples**: Experts in the field of climate change explain climate models and predictions in a simple and understandable way, enhancing public awareness of environmental protection.3. **Updating and Developing Information** - **Role in the Dissemination of New Knowledge and Technologies**: Experts' research and promotion in emerging technologies (such as artificial intelligence, gene editing) have advanced society's understanding and application of new technologies. - **Discussion**: How do experts stay updated in a rapidly changing information environment to ensure the accuracy and timeliness of information. Part Three: The Impact of Experts in Education1. **Design and Implementation of Educational Content** - **Role in Curriculum Development**: Experts participate in curriculum design to ensure the scientific and cutting-edge nature of educational content. - **Case Study**: Involvement of experts in education reform, promoting the implementation of STEM education, enhancing students' scientific literacy.2. **Teaching Methods and Strategies** - **Influencing the Choice of Teaching Methods**: Experts' research findings and teaching strategies help teachers improve their teaching methods. - **Discussion**: How collaboration between experts and teachers promotes educational innovation and enhances teaching effectiveness.3. **Students' Learning Experience** - **Impact of Expert Lectures and Workshops**: The involvement of experts can inspire students' interest in learning and broaden their horizons. - **Examples**: Projects involving experts (such as scientific experiments, social research) have enhanced the effectiveness of student capabilities, strengthening the integration of practice and theory. Part Four: Challenges and Opportunities for Experts1. **Information Overload and Misinformation** - **Challenges of the Information Age**: How experts maintain authority in the sea of information and avoid being overwhelmed by misinformation. - **Discussion**: How the public discerns the authority of experts and how experts enhance their credibility.2. **Impact of Technology** - **Influence of the Digital Age on the Role of Experts**: Online education and social media have changed the way experts interact with the public. - **Examples**: How experts' participation on online education platforms expands their influence through the internet.3. **Building Public Trust** - **Establishing Trust with the Public**: How experts build trust through transparent communication and active public engagement. - **Case Studies**: How successful and failed expert images influence public trust in experts. ConclusionSummarizing the Importance of Experts: Experts play an indispensable role in informational and educational content, influencing the dissemination of information and educational outcomes.Future Outlook: In emerging fields and technologies, the role of experts will continue to evolve, and adapting to change will be an important topic in the future. References- List relevant academic articles, books, and other resources to support the arguments and analysis in this article.---This outline provides a structure for an article on the role and impact of experts in informational and educational content, covering the definition, roles, influence, challenges, and future prospects of experts. Each section can be expanded into detailed content of 1000-2000 words as needed.Outline: The Role and Impact of Experts in Informational/Educational Content IntroductionThe Importance of Experts: In the age of information explosion, experts play a crucial role as disseminators of knowledge and guides in education. They not only provide authoritative information but also help the public understand complex concepts.Purpose of the Article: To explore how experts influence information dissemination and educational outcomes, analyze their roles in different fields, and the challenges they face. Part One: Definition and Role of Experts1. **Definition of Experts** - **Basic Characteristics**: Experts typically possess deep professional knowledge, extensive practical experience, and high academic achievements. - **Types of Experts in Different Fields**: Including scientists, educators, technical experts, social scholars, etc., experts in various fields have unique insights and influence within their respective domains.2. **Roles of Experts** - **Disseminators of Knowledge**: By giving lectures, publishing materials, and media appearances, experts help the public access the latest information. - **Drivers of Research and Innovation**: Engaging in research projects, experts drive the development of new technologies and theories. - **Analysts of Social Issues**: Conducting in-depth analysis of societal hot topics, experts provide solutions and policy recommendations. Part Two: The Role of Experts in Information Dissemination1. **Authority of Information** - **Enhancing Credibility of Information**: The involvement of experts can enhance the authority of information, as the public tends to trust expert opinions. - **Case Studies**: In public health crises (such as the COVID-19 pandemic), expert opinions and recommendations have significant influence on public behavior and policy-making.2. **Interpretation and Analysis of Information** - **Helping the Public Understand Complex Information**: Experts can translate technical terms into easily understandable language, helping the public digest complex information. - **Examples**: Experts in the field of climate change explain climate models and predictions in a simple and understandable way, enhancing public awareness of environmental protection.3. **Updating and Developing Information** - **Role in the Dissemination of New Knowledge and Technologies**: Experts' research and promotion in emerging technologies (such as artificial intelligence, gene editing) have advanced society's understanding and application of new technologies. - **Discussion**: How do experts stay updated in a rapidly changing information environment to ensure the accuracy and timeliness of information. Part Three: The Impact of Experts in Education1. **Design and Implementation of Educational Content** - **Role in Curriculum Development**: Experts participate in curriculum design to ensure the scientific and cutting-edge nature of educational content. - **Case Study**: Involvement of experts in education reform, promoting the implementation of STEM education, enhancing students' scientific literacy.2. **Teaching Methods and Strategies** - **Influencing the Choice of Teaching Methods**: Experts' research findings and teaching strategies help teachers improve their teaching methods. - **Discussion**: How collaboration between experts and teachers promotes educational innovation and enhances teaching effectiveness.3. **Students' Learning Experience** - **Impact of Expert Lectures and Workshops**: The involvement of experts can inspire students' interest in learning and broaden their horizons. - **Examples**: Projects involving experts (such as scientific experiments, social research) have enhanced the effectiveness of student capabilities, strengthening the integration of practice and theory. Part Four: Challenges and Opportunities for Experts1. **Information Overload and Misinformation** - **Challenges of the Information Age**: How experts maintain authority in the sea of information and avoid being overwhelmed by misinformation. - **Discussion**: How the public discerns the authority of experts and how experts enhance their credibility.2. **Impact of Technology** - **Influence of the Digital Age on the Role of Experts**: Online education and social media have changed the way experts interact with the public. - **Examples**: How experts' participation on online education platforms expands their influence through the internet.3. **Building Public Trust** - **Establishing Trust with the Public**: How experts build trust through transparent communication and active public engagement. - **Case Studies**: How successful and failed expert images influence public trust in experts. ConclusionSummarizing the Importance of Experts: Experts play an indispensable role in informational and educational content, influencing the dissemination of information and educational outcomes.Future Outlook: In emerging fields and technologies, the role of experts will continue to evolve, and adapting to change will be an important topic in the future. References- List relevant academic articles, books, and other resources to support the arguments and analysis in this article.---This outline provides a structure for an article on the role and impact of experts in informational and educational content, covering the definition, roles, influence, challenges, and future prospects of experts. Each section can be expanded into detailed content of 1000-2000 words as needed.

Analysis of Popular Jinhuanyu Wire and Cable Models and Prices IntroductionIn modern society, wire and cable, as an important part of infrastructure, are widely used in various industries such as construction, electricity, and communication. Jinhuanyu wire and cable, with its high-quality products and good market reputation, has gradually become a leader in the industry. The supply of spot wire and cable can not only meet the immediate needs of the market but also effectively reduce the construction period of projects. Therefore, understanding the popular models and prices of Jinhuanyu wire and cable is of great reference value for consumers and industry practitioners. This article will provide an in-depth analysis of the popular models and prices of Jinhuanyu wire and cable. 1. Overview of Jinhuanyu Wire and Cable 1.1 Company BackgroundEstablished in the 1990s, Jinhuanyu Wire and Cable has become an important participant in the domestic wire and cable industry after many years of development. The company is dedicated to the research, production, and sales of various wire and cable products, covering low-voltage cables, medium-voltage cables, high-voltage cables, and special cables. With its advanced production equipment and strict quality management system, Jinhuanyu has won the trust of a large number of customers. 1.2 Applications of Wire and CableJinhuanyu wire and cable have a wide range of applications, mainly including:Construction industry: used for power supply, lighting, and safety systems in buildings.Electricity industry: used for power transmission and distribution to ensure the stable operation of the power system.Communication industry: used for data transmission and signal delivery to support the construction of modern communication networks.Other industries: such as transportation, manufacturing, and other fields, Jinhuanyu wire and cable also play an important role. 2. Analysis of Popular Models 2.1 Introduction to Common ModelsJinhuanyu wire and cable have a wide range of product models, some of the popular models include:BV (Copper Core PVC Insulated Wire): Suitable for household and industrial power wiring, with good conductivity and insulation performance.BVR (Copper Core PVC Insulated Flexible Wire): Compared to BV, BVR is more flexible and suitable for applications that require frequent bending.YJV (Cross-linked Polyethylene Insulated Power Cable): Suitable for power transmission, with excellent heat resistance and pressure resistance, suitable for high-voltage environments. 2.2 Performance ComparisonWhen choosing wire and cable, performance is an important consideration. Here is a performance comparison of popular models:Conductor material: BV and BVR use high-quality copper material to ensure good conductivity; YJV uses cross-linked polyethylene material to enhance the cable's heat resistance.Insulation material: BV and BVR have PVC insulation layers with good insulation performance; YJV uses cross-linked polyethylene, which has a wider temperature range.Temperature resistance, pressure resistance, and other performance indicators: The temperature resistance range of BV and BVR is generally around 70°C, while YJV can reach up to 90°C, suitable for high-voltage environments. 3. Price Factor Analysis 3.1 Price CompositionThe price of Jinhuanyu wire and cable is influenced by various factors, including:Raw material costs: Fluctuations in the prices of copper and insulation materials directly affect the production cost of cables.Production process: Advanced production processes and equipment investment can improve production efficiency but also increase costs.Market demand and supply: Changes in market demand and supply fluctuations can lead to price fluctuations. 3.2 Spot Price TrendsRecently, the market price of Jinhuanyu wire and cable has experienced some fluctuations. Due to changes in the global economic situation, the rise in raw material prices has led to an increase in cable prices. In addition, policy adjustments and changes in the international market also affect prices. 4. Overview of Popular Model Prices 4.1 Price Range of Each ModelHere are the price ranges of popular models of Jinhuanyu wire and cable (in Chinese Yuan):| Model | Price Range (RMB/meter) ||------|-------------------|| BV | 2.5 - 5.0 || BVR | 3.0 - 6.0 || YJV | 10.0 - 20.0 |It is important to note that prices may vary due to different regions and market demands. 4.2 Relationship between Price and PerformanceWhen choosing wire and cable, the relationship between price and performance is crucial. Although BV and BVR are relatively low-priced, in some high-load or high-temperature environments, YJV may be a better choice. Therefore, consumers should consider their actual needs when making a choice. 5. Buying Recommendations 5.1 Factors to Consider When Choosing the Right ModelWhen choosing Jinhuanyu wire and cable, consumers should consider the following factors:Usage environment: Different environments have different performance requirements for cables, such as humidity, high temperature, etc.Load requirements: Choose the appropriate model based on the actual electrical load to ensure safe use.Budget constraints: Choose products with high cost performance while meeting performance requirements. 5.2 Recommended Purchase ChannelsConsumers can purchase Jinhuanyu wire and cable through various channels, including:Online channels: such as e-commerce platforms, convenient and fast, but be sure to choose reputable merchants.Offline channels: such as building materials markets and specialty stores, where you can directly view product quality.The importance of choosing a regular supplier: Ensure product quality and after-sales service to avoid quality issues due to low prices. 6. ConclusionJinhuanyu wire and cable, with its high-quality products and good market reputation, has become an important participant in the wire and cable industry. Through the analysis of popular models and their prices, we can better understand market dynamics and product characteristics. When choosing wire and cable, consumers should consider the usage environment, load requirements, and budget constraints to choose the right model. At the same time, choosing a regular supplier is also crucial to ensure product quality and after-sales service. Looking ahead, Jinhuanyu wire and cable still have broad prospects in the market. With the continuous advancement of technology and changes in market demand, Jinhuanyu will continue to provide customers with better products and services. References- Industry reports- Professional websites and forums- Relevant books and materialsThe above is an analysis article on the models and prices of Jinhuanyu wire and cable, hoping to provide valuable references for you when choosing wire and cable. Analysis of Popular Jinhuanyu Wire and Cable Models and Prices IntroductionIn modern society, wire and cable, as an important part of infrastructure, are widely used in various industries such as construction, electricity, and communication. Jinhuanyu wire and cable, with its high-quality products and good market reputation, has gradually become a leader in the industry. The supply of spot wire and cable can not only meet the immediate needs of the market but also effectively reduce the construction period of projects. Therefore, understanding the popular models and prices of Jinhuanyu wire and cable is of great reference value for consumers and industry practitioners. This article will provide an in-depth analysis of the popular models and prices of Jinhuanyu wire and cable. 1. Overview of Jinhuanyu Wire and Cable 1.1 Company BackgroundEstablished in the 1990s, Jinhuanyu Wire and Cable has become an important participant in the domestic wire and cable industry after many years of development. The company is dedicated to the research, production, and sales of various wire and cable products, covering low-voltage cables, medium-voltage cables, high-voltage cables, and special cables. With its advanced production equipment and strict quality management system, Jinhuanyu has won the trust of a large number of customers. 1.2 Applications of Wire and CableJinhuanyu wire and cable have a wide range of applications, mainly including:Construction industry: used for power supply, lighting, and safety systems in buildings.Electricity industry: used for power transmission and distribution to ensure the stable operation of the power system.Communication industry: used for data transmission and signal delivery to support the construction of modern communication networks.Other industries: such as transportation, manufacturing, and other fields, Jinhuanyu wire and cable also play an important role. 2. Analysis of Popular Models 2.1 Introduction to Common ModelsJinhuanyu wire and cable have a wide range of product models, some of the popular models include:BV (Copper Core PVC Insulated Wire): Suitable for household and industrial power wiring, with good conductivity and insulation performance.BVR (Copper Core PVC Insulated Flexible Wire): Compared to BV, BVR is more flexible and suitable for applications that require frequent bending.YJV (Cross-linked Polyethylene Insulated Power Cable): Suitable for power transmission, with excellent heat resistance and pressure resistance, suitable for high-voltage environments. 2.2 Performance ComparisonWhen choosing wire and cable, performance is an important consideration. Here is a performance comparison of popular models:Conductor material: BV and BVR use high-quality copper material to ensure good conductivity; YJV uses cross-linked polyethylene material to enhance the cable's heat resistance.Insulation material: BV and BVR have PVC insulation layers with good insulation performance; YJV uses cross-linked polyethylene, which has a wider temperature range.Temperature resistance, pressure resistance, and other performance indicators: The temperature resistance range of BV and BVR is generally around 70°C, while YJV can reach up to 90°C, suitable for high-voltage environments. 3. Price Factor Analysis 3.1 Price CompositionThe price of Jinhuanyu wire and cable is influenced by various factors, including:Raw material costs: Fluctuations in the prices of copper and insulation materials directly affect the production cost of cables.Production process: Advanced production processes and equipment investment can improve production efficiency but also increase costs.Market demand and supply: Changes in market demand and supply fluctuations can lead to price fluctuations. 3.2 Spot Price TrendsRecently, the market price of Jinhuanyu wire and cable has experienced some fluctuations. Due to changes in the global economic situation, the rise in raw material prices has led to an increase in cable prices. In addition, policy adjustments and changes in the international market also affect prices. 4. Overview of Popular Model Prices 4.1 Price Range of Each ModelHere are the price ranges of popular models of Jinhuanyu wire and cable (in Chinese Yuan):| Model | Price Range (RMB/meter) ||------|-------------------|| BV | 2.5 - 5.0 || BVR | 3.0 - 6.0 || YJV | 10.0 - 20.0 |It is important to note that prices may vary due to different regions and market demands. 4.2 Relationship between Price and PerformanceWhen choosing wire and cable, the relationship between price and performance is crucial. Although BV and BVR are relatively low-priced, in some high-load or high-temperature environments, YJV may be a better choice. Therefore, consumers should consider their actual needs when making a choice. 5. Buying Recommendations 5.1 Factors to Consider When Choosing the Right ModelWhen choosing Jinhuanyu wire and cable, consumers should consider the following factors:Usage environment: Different environments have different performance requirements for cables, such as humidity, high temperature, etc.Load requirements: Choose the appropriate model based on the actual electrical load to ensure safe use.Budget constraints: Choose products with high cost performance while meeting performance requirements. 5.2 Recommended Purchase ChannelsConsumers can purchase Jinhuanyu wire and cable through various channels, including:Online channels: such as e-commerce platforms, convenient and fast, but be sure to choose reputable merchants.Offline channels: such as building materials markets and specialty stores, where you can directly view product quality.The importance of choosing a regular supplier: Ensure product quality and after-sales service to avoid quality issues due to low prices. 6. ConclusionJinhuanyu wire and cable, with its high-quality products and good market reputation, has become an important participant in the wire and cable industry. Through the analysis of popular models and their prices, we can better understand market dynamics and product characteristics. When choosing wire and cable, consumers should consider the usage environment, load requirements, and budget constraints to choose the right model. At the same time, choosing a regular supplier is also crucial to ensure product quality and after-sales service. Looking ahead, Jinhuanyu wire and cable still have broad prospects in the market. With the continuous advancement of technology and changes in market demand, Jinhuanyu will continue to provide customers with better products and services. References- Industry reports- Professional websites and forums- Relevant books and materialsThe above is an analysis article on the models and prices of Jinhuanyu wire and cable, hoping to provide valuable references for you when choosing wire and cable.

How to Choose Off-the-Shelf Capacitor Equipment

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and timing. They store electrical energy temporarily and release it when needed, making them essential for the smooth operation of electronic devices. Selecting the right capacitor equipment is crucial, as it can significantly impact the performance, reliability, and longevity of your electronic designs. This article aims to guide you through the process of choosing off-the-shelf capacitor equipment, covering the basics of capacitors, application requirements, performance characteristics, sourcing options, cost considerations, and testing methods.

II. Understanding Capacitor Basics

A. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Known for their small size and low cost, ceramic capacitors are widely used in high-frequency applications. They have low equivalent series resistance (ESR) and are stable over a range of temperatures.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are typically used in power supply circuits. However, they have polarity and can be sensitive to voltage spikes.

3. **Film Capacitors**: Film capacitors are known for their stability and low loss characteristics. They are often used in audio applications and power electronics.

4. **Tantalum Capacitors**: Tantalum capacitors provide high capacitance in a small package and are used in applications requiring reliability, such as medical devices and aerospace.

5. **Supercapacitors**: These capacitors can store large amounts of energy and are used in applications requiring quick bursts of power, such as in regenerative braking systems.

B. Key Specifications

When selecting capacitors, consider the following key specifications:

1. **Capacitance Value**: This is the measure of a capacitor's ability to store charge, typically expressed in microfarads (µF) or picofarads (pF).

2. **Voltage Rating**: The maximum voltage a capacitor can handle without failing. Always choose a capacitor with a voltage rating higher than the maximum voltage it will encounter in the circuit.

3. **Tolerance**: This indicates how much the actual capacitance can vary from the stated value. Tighter tolerances are essential for precision applications.

4. **Equivalent Series Resistance (ESR)**: A measure of the resistive losses in a capacitor. Lower ESR values are preferable for high-frequency applications.

5. **Temperature Coefficient**: This indicates how capacitance changes with temperature. Different applications may require capacitors with specific temperature coefficients.

III. Identifying Application Requirements

A. Analyzing the Specific Application

Understanding the specific application is crucial for selecting the right capacitor. Different applications have unique requirements:

1. **Power Supply Circuits**: Capacitors in power supplies must handle ripple currents and voltage spikes, making low ESR and high voltage ratings essential.

2. **Signal Processing**: In signal processing applications, capacitors must maintain stability and low distortion, often requiring film or ceramic capacitors.

3. **Timing Applications**: Timing circuits rely on precise capacitance values, making tolerance and temperature coefficients critical.

B. Environmental Considerations

Environmental factors can significantly affect capacitor performance:

1. **Operating Temperature Range**: Ensure the capacitor can operate within the temperature range of your application.

2. **Humidity and Moisture Exposure**: Some capacitors are more susceptible to moisture, which can lead to failure. Consider using sealed or conformally coated capacitors in humid environments.

3. **Mechanical Stress and Vibration**: In applications subject to vibration, choose capacitors with robust construction to prevent failure.

IV. Evaluating Performance Characteristics

A. Frequency Response

Capacitors behave differently at various frequencies:

1. **Self-Resonant Frequency**: This is the frequency at which the capacitor's reactance equals its resistance. Above this frequency, the capacitor behaves more like an inductor.

2. **Impedance Characteristics**: Understanding how impedance changes with frequency is crucial for applications like RF circuits.

B. Lifespan and Reliability

The reliability of capacitors is paramount, especially in critical applications:

1. **Failure Rates and MTBF**: Look for capacitors with low failure rates and high Mean Time Between Failures (MTBF) ratings.

2. **Aging Effects**: Some capacitors, particularly electrolytic types, can degrade over time. Consider the expected lifespan in your application.

C. Size and Form Factor

The physical size of the capacitor can impact your design:

1. **PCB Space Constraints**: Ensure the capacitor fits within the available space on your printed circuit board (PCB).

2. **Mounting Options**: Decide between through-hole and surface mount capacitors based on your assembly process and design requirements.

V. Sourcing Off-the-Shelf Capacitor Equipment

A. Reputable Manufacturers and Suppliers

Choosing a reliable supplier is essential:

1. **Brand Reputation and Reliability**: Research manufacturers known for quality and reliability in capacitor production.

2. **Product Certifications and Standards**: Look for capacitors that meet industry standards, such as ISO or RoHS compliance.

B. Comparison Shopping

When sourcing capacitors, consider:

1. **Price vs. Performance**: Balance cost with performance characteristics to find the best value.

2. **Availability and Lead Times**: Ensure the capacitors you choose are readily available to avoid delays in your project.

C. Technical Support and Documentation

Access to technical resources is vital:

1. **Datasheets and Application Notes**: Review datasheets for detailed specifications and application notes for guidance on usage.

2. **Customer Service and Technical Assistance**: Choose suppliers that offer robust customer support for troubleshooting and technical inquiries.

VI. Cost Considerations

A. Budget Constraints

Establish a budget for your capacitor selection process, considering both initial costs and long-term expenses.

B. Cost vs. Quality Trade-offs

While it may be tempting to choose the cheapest option, consider the potential impact on performance and reliability.

C. Long-term Value and Total Cost of Ownership

Evaluate the total cost of ownership, including maintenance and replacement costs, to make an informed decision.

VII. Testing and Validation

A. Importance of Prototype Testing

Before finalizing your capacitor choice, prototype testing is essential to validate performance in real-world conditions.

B. Methods for Testing Capacitor Performance

1. **Bench Testing**: Conduct tests to measure capacitance, ESR, and other key parameters.

2. **Simulation Tools**: Use simulation software to model capacitor behavior in your circuit design.

C. Iterative Design and Feedback Loops

Incorporate feedback from testing into your design process, allowing for adjustments and improvements.

VIII. Conclusion

Selecting the right off-the-shelf capacitor equipment is a critical step in the design of electronic circuits. By understanding capacitor basics, identifying application requirements, evaluating performance characteristics, sourcing from reputable suppliers, considering costs, and conducting thorough testing, you can make informed decisions that enhance the reliability and performance of your designs. Take the time to research and validate your choices, ensuring that your capacitor selection meets the demands of your specific application.

IX. References

For further exploration of capacitor selection and applications, consider the following resources:

- "Capacitor Handbook" by John Smith

- "Understanding Capacitors" - IEEE Standards

- Manufacturer datasheets and application notes from reputable capacitor suppliers

By following these guidelines, you can confidently choose the right off-the-shelf capacitor equipment for your electronic projects.

Similar Recommendations for Washing Machine Capacitor Components

I. Introduction

Washing machines are essential appliances in modern households, providing convenience and efficiency in laundry care. At the heart of their operation lies a crucial component: the capacitor. Capacitors play a significant role in the functionality of washing machines, particularly in the operation of motors. This article aims to provide recommendations for selecting capacitor components, ensuring that your washing machine operates smoothly and efficiently.

II. Understanding Capacitors in Washing Machines

A. Definition and Function of Capacitors

A capacitor is an electrical component that stores and releases electrical energy. In washing machines, capacitors are primarily used to manage the electrical current that powers the motor. They help in starting the motor and maintaining its operation, ensuring that the washing machine functions as intended.

B. Types of Capacitors Used in Washing Machines

There are three main types of capacitors commonly found in washing machines:

1. **Start Capacitors**: These capacitors provide a boost of energy to start the motor. They are typically used in single-phase motors and are designed to discharge quickly to help the motor reach its operating speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit while the motor is running. They help improve the motor's efficiency and performance by providing a continuous supply of energy.

3. **Dual Run Capacitors**: These capacitors combine the functions of both start and run capacitors. They are used in applications where both starting and running capabilities are needed, making them versatile components in washing machines.

C. Role of Capacitors in Motor Operation and Energy Efficiency

Capacitors are vital for the efficient operation of washing machine motors. They help in reducing energy consumption by ensuring that the motor runs smoothly and efficiently. A well-functioning capacitor can lead to lower electricity bills and a longer lifespan for the washing machine.

III. Common Issues with Washing Machine Capacitors

A. Signs of Capacitor Failure

Capacitor failure can lead to various issues in washing machines. Here are some common signs to watch for:

1. **Unusual Noises**: If you hear humming, buzzing, or clicking sounds coming from the washing machine, it may indicate a failing capacitor.

2. **Motor Not Starting**: A capacitor that has failed may prevent the motor from starting altogether. If the machine does not respond when you turn it on, the capacitor could be the culprit.

3. **Intermittent Operation**: If the washing machine operates sporadically or shuts off unexpectedly, it may be due to a faulty capacitor.

B. Consequences of Faulty Capacitors

Ignoring capacitor issues can lead to several negative consequences:

1. **Reduced Efficiency**: A malfunctioning capacitor can cause the motor to work harder, leading to decreased efficiency and longer wash cycles.

2. **Potential Damage to the Motor**: Prolonged use of a washing machine with a faulty capacitor can result in damage to the motor, leading to costly repairs or replacements.

3. **Increased Energy Consumption**: A failing capacitor can cause the washing machine to draw more power, resulting in higher energy bills.

IV. Recommendations for Selecting Capacitor Components

A. Key Specifications to Consider

When selecting capacitor components for your washing machine, consider the following specifications:

1. **Voltage Rating**: Ensure that the capacitor's voltage rating matches or exceeds the voltage requirements of your washing machine. Using a capacitor with a lower voltage rating can lead to failure.

2. **Capacitance Value**: The capacitance value, measured in microfarads (µF), is crucial for the proper functioning of the motor. Refer to the manufacturer's specifications to determine the correct capacitance value.

3. **Temperature Rating**: Capacitors are rated for specific temperature ranges. Choose a capacitor that can withstand the operating temperatures of your washing machine to ensure longevity.

B. Quality and Reliability of Components

1. **Importance of Brand Reputation**: Opt for capacitors from reputable manufacturers known for their quality and reliability. Established brands often have a track record of producing durable components.

2. **Certifications and Standards**: Look for capacitors that meet industry standards and certifications, such as UL (Underwriters Laboratories) or CE (Conformité Européenne). These certifications indicate that the components have been tested for safety and performance.

C. Compatibility with Washing Machine Models

1. **Manufacturer Specifications**: Always refer to the washing machine's user manual or manufacturer specifications when selecting capacitor components. This ensures compatibility and optimal performance.

2. **Cross-Referencing with Existing Components**: If you are replacing a capacitor, cross-reference the new component with the existing one to ensure it matches in terms of specifications and dimensions.

V. Recommended Brands and Products

A. Overview of Reputable Capacitor Manufacturers

When it comes to selecting capacitor components, several brands stand out for their quality and reliability:

1. **Brand A**: Known for its high-performance capacitors, Brand A offers a range of products suitable for various washing machine models. Their capacitors are designed for durability and efficiency.

2. **Brand B**: With a focus on innovation, Brand B provides capacitors that meet the latest industry standards. Their products are backed by excellent customer support and warranties.

3. **Brand C**: Brand C is recognized for its cost-effective solutions without compromising on quality. Their capacitors are widely used in the appliance industry and have received positive reviews from users.

B. Comparison of Product Lines

When comparing capacitor products, consider the following factors:

1. **Price vs. Performance**: While it may be tempting to choose the cheapest option, consider the long-term performance and reliability of the capacitor. Investing in a higher-quality component can save you money on repairs in the future.

2. **Warranty and Customer Support**: Look for brands that offer warranties on their products. Good customer support can also be invaluable if you encounter issues with the capacitor.

VI. Installation and Maintenance Tips

A. Safety Precautions When Handling Capacitors

When working with capacitors, safety should be your top priority. Always discharge capacitors before handling them to avoid electric shock. Use insulated tools and wear protective gear, such as gloves and safety glasses.

B. Step-by-Step Guide to Replacing a Washing Machine Capacitor

1. **Unplug the Washing Machine**: Ensure the machine is disconnected from the power source.

2. **Access the Capacitor**: Remove the back panel or access cover to reach the capacitor.

3. **Disconnect the Old Capacitor**: Take note of the wiring configuration and carefully disconnect the old capacitor.

4. **Install the New Capacitor**: Connect the new capacitor, ensuring that the wiring matches the original configuration.

5. **Reassemble the Washing Machine**: Replace the access cover and plug the machine back in.

6. **Test the Machine**: Run a short cycle to ensure the washing machine operates correctly.

C. Regular Maintenance Practices to Prolong Capacitor Life

To extend the life of your washing machine's capacitors, consider the following maintenance practices:

1. **Regular Inspections**: Periodically check the capacitors for signs of wear or damage.

2. **Keep the Area Clean**: Ensure that the area around the washing machine is clean and free of debris that could affect the components.

3. **Avoid Overloading**: Do not overload the washing machine, as this can put additional strain on the motor and capacitors.

VII. Conclusion

Selecting the right capacitor components for your washing machine is crucial for maintaining its efficiency and performance. By understanding the types of capacitors, recognizing signs of failure, and following recommendations for selection and installation, you can ensure that your washing machine operates smoothly for years to come. Prioritizing quality and compatibility will not only enhance the performance of your appliance but also contribute to energy savings and longevity. Remember, proper care and maintenance of your washing machine's capacitors are key to keeping it running efficiently.

VIII. References

- Manufacturer specifications and user manuals for various washing machine models.

- Industry standards and certifications for electrical components.

- Reviews and comparisons of capacitor brands and products.

By following the guidelines outlined in this article, you can make informed decisions regarding washing machine capacitor components, ensuring optimal performance and reliability in your laundry care routine.

Capacity Specifications of the Latest Capacitors

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from smoothing out voltage fluctuations in power supplies to enabling high-frequency signal processing in communication devices. Over the years, capacitor technology has evolved significantly, leading to improvements in capacity, efficiency, and reliability. This article aims to explore the latest capacity specifications of capacitors, highlighting the advancements that have shaped the current landscape of capacitor technology.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Understanding these types is essential for selecting the right capacitor for specific needs.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components known for their high capacitance values, making them ideal for applications requiring significant energy storage. They are commonly used in power supply circuits and audio equipment. The capacity specifications of modern electrolytic capacitors can reach up to several thousand microfarads (µF), with voltage ratings typically ranging from 6.3V to 450V.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and widely used in high-frequency applications due to their low equivalent series resistance (ESR). They are available in various capacitance values, typically ranging from picofarads (pF) to microfarads (µF). The latest ceramic capacitors can achieve high capacitance values while maintaining small physical sizes, making them suitable for compact electronic devices.

C. Film Capacitors

Film capacitors are known for their stability and reliability, making them ideal for applications in audio equipment, power electronics, and industrial machinery. They typically have capacitance values ranging from nanofarads (nF) to microfarads (µF). Recent advancements have led to the development of high-energy film capacitors that can handle higher voltage ratings and offer improved performance.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability over a wide temperature range. They are commonly used in applications such as mobile devices and medical equipment. The latest tantalum capacitors can achieve capacitance values in the range of microfarads (µF) with voltage ratings up to 50V or more.

E. Supercapacitors

Supercapacitors, also known as ultracapacitors, are designed for high energy storage and rapid charge/discharge cycles. They are increasingly used in applications such as energy harvesting, electric vehicles, and renewable energy systems. The latest supercapacitors can achieve capacitance values in the farad (F) range, making them suitable for applications requiring quick bursts of energy.

III. Factors Influencing Capacitor Capacity

Several factors influence the capacity specifications of capacitors, impacting their performance and suitability for various applications.

A. Dielectric Material

The dielectric material used in capacitors significantly affects their capacity and performance. Common dielectric materials include ceramic, polyester, polypropylene, and tantalum oxide. Each material has unique properties that influence the capacitor's capacitance, voltage rating, and temperature stability.

B. Physical Size and Form Factor

There is a direct relationship between the physical size of a capacitor and its capacity. Generally, larger capacitors can store more energy. However, trends in miniaturization have led to the development of smaller capacitors with higher capacitance values, allowing for more compact electronic designs.

C. Voltage Rating

The voltage rating of a capacitor is crucial in determining its capacity specifications. Exceeding the voltage rating can lead to capacitor failure, affecting performance and reliability. Manufacturers are continually improving voltage ratings, allowing capacitors to operate safely at higher voltages without compromising capacity.

D. Temperature and Environmental Factors

Temperature can significantly impact capacitor capacity. High temperatures can lead to increased leakage currents and reduced lifespan, while low temperatures can affect performance. Capacitors are designed to operate within specific temperature ranges, and understanding these factors is essential for selecting the right component for a given environment.

IV. Latest Innovations in Capacitor Technology

The capacitor industry is witnessing several innovations that enhance capacity specifications and overall performance.

A. Advancements in Materials

New dielectric materials are being developed to improve the efficiency and capacity of capacitors. For example, the use of high-k dielectrics allows for increased capacitance in smaller packages, making them ideal for modern electronic devices.

B. Enhanced Manufacturing Techniques

Manufacturing techniques have evolved to improve the reliability and performance of capacitors. Techniques such as thin-film deposition and advanced winding methods enable the production of capacitors with higher capacity and lower ESR, enhancing their overall efficiency.

C. Smart Capacitors

Smart capacitors are an emerging technology that incorporates sensors and communication capabilities. These capacitors can monitor their performance and provide real-time data, allowing for better management of energy storage systems and improved reliability in critical applications.

V. Capacity Specifications of Current Capacitor Models

The market is filled with a variety of capacitor models, each with unique capacity specifications. Here, we will compare some of the leading manufacturers and their offerings.

A. Overview of Leading Manufacturers

Leading manufacturers such as Murata, Nichicon, KEMET, and Maxwell Technologies are at the forefront of capacitor technology, continuously innovating to meet the demands of modern electronics.

B. Comparison of Capacity Specifications Across Different Types

1. **High-Capacity Electrolytic Capacitors**: Capacitors from Nichicon can reach up to 10,000 µF with voltage ratings of 450V.

2. **High-Frequency Ceramic Capacitors**: Murata's latest offerings can achieve capacitance values of up to 1 µF with voltage ratings exceeding 100V.

3. **High-Energy Film Capacitors**: KEMET's film capacitors can reach capacitance values of 100 µF with voltage ratings of 1,000V.

4. **Advanced Supercapacitors**: Maxwell Technologies produces supercapacitors with capacitance values of up to 3,000 F, suitable for energy storage applications.

C. Case Studies of Specific Models

1. **Model A**: Nichicon's UHE Series electrolytic capacitors are designed for high-capacity applications, offering up to 10,000 µF at 450V, making them ideal for power supply circuits.

2. **Model B**: Murata's GRM Series ceramic capacitors provide high-frequency performance with capacitance values up to 1 µF, suitable for RF applications.

3. **Model C**: KEMET's A750 Series film capacitors are designed for high-energy applications, offering capacitance values of 100 µF at 1,000V, ideal for industrial machinery.

VI. Applications of High-Capacity Capacitors

High-capacity capacitors find applications across various industries, demonstrating their versatility and importance.

A. Consumer Electronics

In consumer electronics, capacitors play a vital role in smartphones, tablets, and laptops, ensuring stable power supply and efficient energy management.

B. Renewable Energy Systems

Capacitors are essential in renewable energy systems, such as solar inverters and wind turbines, where they help manage energy storage and improve system efficiency.

C. Electric Vehicles

In electric vehicles, capacitors are crucial for battery management systems, enabling efficient energy transfer and enhancing overall performance.

D. Industrial Applications

Capacitors are widely used in industrial applications, including power supplies and motor drives, where they help maintain stable operation and improve energy efficiency.

VII. Future Trends in Capacitor Technology

The future of capacitor technology is promising, with several trends expected to shape the industry.

A. Predictions for Capacity Advancements

As technology continues to evolve, we can expect further advancements in capacitor capacity, with manufacturers focusing on developing higher-capacity components in smaller packages.

B. Potential Impact of Emerging Technologies

Emerging technologies, such as electric vehicles and renewable energy systems, will drive demand for advanced capacitors, leading to innovations that enhance performance and efficiency.

C. Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in capacitor manufacturing. Manufacturers are exploring eco-friendly materials and production processes to reduce environmental impact.

VIII. Conclusion

In conclusion, the capacity specifications of capacitors are critical to their performance in various applications. As technology continues to advance, we can expect to see significant improvements in capacitor capacity, efficiency, and reliability. Understanding the different types of capacitors, the factors influencing their capacity, and the latest innovations in the field will help engineers and designers make informed decisions when selecting capacitors for their projects. The future of capacitor technology is bright, with exciting developments on the horizon that will continue to shape the electronics industry.

IX. References

A comprehensive list of academic papers, articles, and resources used for research, along with suggested further reading for interested readers, can be provided upon request.

How Should the Off-the-Shelf Capacitor Structure Be Selected?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and signal coupling. Their selection is crucial in electronic design, as the right capacitor can significantly impact the performance, reliability, and longevity of a circuit. This blog post will explore how to select off-the-shelf capacitor structures, providing insights into the types of capacitors available, their specifications, application requirements, performance characteristics, and practical selection processes.

II. Understanding Capacitor Basics

A. Types of Capacitors

Capacitors come in various types, each with unique characteristics suited for specific applications:

1. **Ceramic Capacitors**: Known for their small size and high capacitance-to-volume ratio, ceramic capacitors are widely used in high-frequency applications. They are non-polarized and exhibit low equivalent series resistance (ESR), making them ideal for decoupling and filtering.

2. **Electrolytic Capacitors**: These capacitors offer high capacitance values and are typically used in power supply circuits. They are polarized, meaning they must be connected in the correct orientation to function properly. However, they have higher ESR and lower frequency response compared to ceramic capacitors.

3. **Film Capacitors**: Film capacitors are known for their stability and low loss characteristics. They are often used in applications requiring high precision and reliability, such as audio equipment and timing circuits.

4. **Tantalum Capacitors**: Tantalum capacitors provide high capacitance in a small package and are known for their reliability. They are also polarized and are commonly used in compact electronic devices.

B. Key Specifications

When selecting a capacitor, several key specifications must be considered:

1. **Capacitance Value**: This is the measure of a capacitor's ability to store charge, expressed in farads (F). The required capacitance value will depend on the specific application.

2. **Voltage Rating**: The voltage rating indicates the maximum voltage the capacitor can handle without risk of failure. It is essential to choose a capacitor with a voltage rating higher than the maximum voltage expected in the circuit.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the internal resistance of the capacitor, which affects its efficiency and performance, especially in high-frequency applications.

4. **Temperature Coefficient**: This specification indicates how the capacitance value changes with temperature. Different applications may require capacitors with specific temperature coefficients to ensure stable performance.

5. **Size and Form Factor**: The physical size and shape of the capacitor can impact its placement on a circuit board and overall design. Smaller capacitors are often preferred in compact designs.

III. Application Requirements

A. Identifying the Application

The first step in selecting a capacitor is to identify the specific application. Different applications have varying requirements:

1. **Power Supply Circuits**: Capacitors in power supply circuits are used for smoothing and filtering. High capacitance values and low ESR are typically desired.

2. **Signal Coupling and Decoupling**: In signal processing, capacitors are used to couple or decouple signals. Low ESR and high-frequency response are critical in these applications.

3. **Timing Applications**: Capacitors are often used in timing circuits, where precision and stability are paramount. Film capacitors are commonly chosen for their reliability in these scenarios.

B. Load Conditions

Understanding the load conditions is essential for capacitor selection:

1. **Steady-State vs. Transient Conditions**: Capacitors may experience different stresses under steady-state and transient conditions. It is crucial to consider how the capacitor will perform under both scenarios.

2. **Frequency Response Requirements**: The frequency at which the capacitor will operate can influence its selection. High-frequency applications may require capacitors with low ESR and specific impedance characteristics.

C. Environmental Considerations

Environmental factors can significantly impact capacitor performance:

1. **Operating Temperature Range**: Capacitors have specified temperature ranges within which they operate effectively. Selecting a capacitor that can withstand the expected temperature variations is vital.

2. **Humidity and Moisture Resistance**: In humid environments, capacitors must be resistant to moisture to prevent failure. Some capacitors are designed with coatings or materials that enhance their moisture resistance.

3. **Mechanical Stress and Vibration**: In applications subject to mechanical stress or vibration, capacitors must be robust enough to withstand these conditions without degrading performance.

IV. Performance Characteristics

A. Impedance and Frequency Response

The impedance of a capacitor varies with frequency, affecting its performance in different applications. Understanding the impedance characteristics is crucial for ensuring optimal performance in high-frequency circuits.

B. Lifetime and Reliability

Capacitor reliability is a critical factor in electronic design: